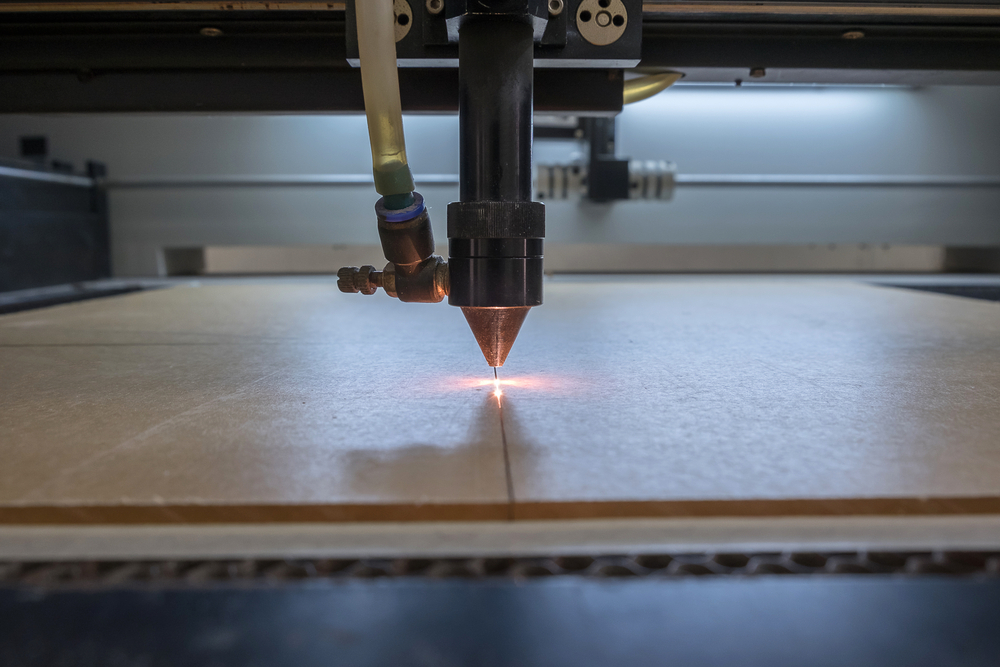

CNC Laser Cutting Machine: How to Laser Cut MDF, Plywood & More

The world of fabrication has been revolutionized by the advent of the CNC laser cutting machine. These machines offer precision, speed, and versatility, making them indispensable in various industries. One of the most common applications is in cutting materials like MDF, plywood, and other wood-based products. In this article, we’ll delve into the process of using a CNC laser cutting machine to cut these materials and provide a handy list of best practices.

Understanding the Basics

Before diving into the specifics, it’s essential to understand what CNC cutting is. CNC laser cutting is a fusion of two powerful technologies. First, there’s CNC, which stands for Computer Numerical Control. This refers to the computerized control of machinery, allowing for precise, repeatable movements. In the context of laser cutting, CNC ensures that the laser moves accurately to create the desired design. The laser itself is a high-intensity light beam capable of melting, burning, or vaporizing materials with extreme precision. This combination of computer control and laser technology allows for intricate designs and patterns to be cut from a variety of materials. As industries strive for efficiency and precision, the adoption of CNC machining services UK and similar technologies worldwide has skyrocketed. The ability to produce complex shapes and designs quickly, without the need for manual intervention, has revolutionized manufacturing and craftsmanship.

Why Use CNC Laser for MDF and Plywood?

MDF and plywood are popular materials in furniture making, crafts, and construction. Using a CNC laser cutter offers several advantages:

- Precision: Laser cutters can achieve intricate designs that are difficult with traditional cutting methods.

- Speed: Automated processes mean faster production times.

- Clean Edges: The laser’s heat seals the edges, reducing the chances of fraying or splintering.

- Versatility: From intricate patterns to simple CNC cutting, laser cutters can handle a wide range of designs.

Steps to Laser Cut MDF, Plywood & More

- Design Preparation: Begin with a digital design. Software like AutoCAD or Illustrator can be used to create your design.

- Material Selection: Ensure the material is free from defects and is of the right thickness. Especially if it’s 6mm MDF board cut to size.

- Machine Setup: Calibrate the laser cutter. Set the power, speed, and frequency based on the material.

- Test Run: Always do a test run on a scrap piece to ensure the settings are correct.

- Cutting: Once satisfied, place the material on the machine bed and start the cutting process.

- Post-processing: After cutting, clean the edges and remove any residue.

Best Practices for CNC Laser Cutting

- Safety First: Always wear protective eyewear and ensure the workspace is well-ventilated.

- Regular Maintenance: Clean the machine’s lens and mirrors to ensure optimal performance. This is crucial when dealing with materials like MDF cut to size.

- Avoid Overheating: MDF and plywood can burn. Monitor the machine and material during the cutting process.

- Stay Updated: Technology evolves. Stay updated with the latest software and techniques to get the best results.

- Use Quality Material: Inferior quality materials can produce inconsistent results. Ensure you’re using the best MDF board for laser cutting.

CNC laser cutting machines have opened up a world of possibilities for craftsmen, designers, and manufacturers. With the right knowledge and practices, one can achieve unparalleled precision and quality in their projects. Whether you’re a seasoned professional or a hobbyist, understanding the intricacies of laser cutting MDF, plywood, and other materials can elevate your work to new heights.

FAQ

Which software can I use to create designs for laser cutting?

Software like AutoCAD or Illustrator is commonly used for creating designs suitable for laser cutting.

Is it safe to use a CNC laser cutting machine?

Yes, but safety precautions are essential. Always wear protective eyewear, ensure the workspace is well-ventilated, and monitor the machine and material to avoid overheating.

What should I do if the edges of my material burn during cutting?

Monitor the machine settings and material during the cutting process. Adjust the power, speed, and frequency settings to avoid overheating and burning.

Is there a risk of the material catching fire during the cutting process?

While the risk is minimal with proper settings and monitoring, there’s always a slight chance. Ensure you have safety measures in place, like a fire extinguisher nearby.