AI-generated website posts offer efficiency for SEO but may lack accuracy and context understanding. While AI boosts content volume and keyword targeting, its limitations can lead to inaccuracies

Edge Band Types: Why Width Always Matters

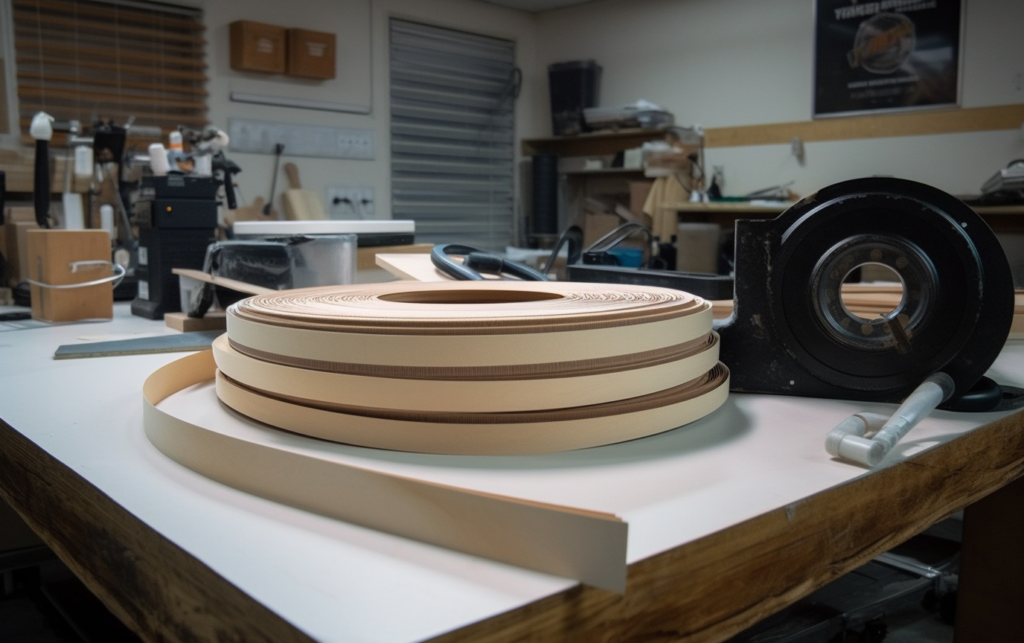

In the intricate world of furniture design and finishing, there’s a subtle element that bears enormous significance — edge banding. The inclusion of edge banding tape into design elements amplifies its importance. It’s not just about the aesthetics but dives deep into durability, functionality, and the holistic look of the furniture piece. While seemingly minor, the width of an edge on any product can profoundly influence its functionality, aesthetics, and overall performance. Width isn’t just about size — it’s about purpose, design, and function.

Why Edge Banding is Non-negotiable

- Aesthetic Finish: The first impression of a piece of furniture often lies in its finishing touches. At the crossroads of design and durability, the edge band offers more than mere protection; it accentuates the furniture’s beauty. By meticulously matching the edging with various boards, the raw edges are transformed into visually appealing masterpieces. The result is a harmonious blend that enriches the overall appearance, ensuring that the furniture not only stands out for its functionality but also its refined elegance. Moreover, techniques like spraying MDF further elevate this elegance, ensuring a flawless finish.

- Functionality: The main function of furniture is utility, which is separate from its aesthetic appeal. A furniture piece, no matter how beautiful, loses its charm if not functional. Edge banding not only ensures the user’s safety but also guarantees that drawers slide smoothly, doors close perfectly, and surfaces remain even. It’s the significant difference between a piece of furniture that merely looks good and one that seamlessly integrates into daily life.

- Durability: Edging plays a fundamental role in fortifying furniture pieces against the rigors of daily use. Consider this: the raw edges of furniture are often more susceptible to wear, tear, and moisture penetration. With widths like 12mm edge banding, especially in materials like MDF, there’s enhanced durability and resistance to wear and tear. Over time, this protection helps in resisting chipping, peeling, or even swelling — ensuring that the furniture remains robust and maintains its form and function for years to come.

- Safety Concerns: In tools or equipment, the edge’s width can either pose a safety threat or mitigate potential risks. Rounded, wider edges are typically safer to touch and reduce the risk of injury. But it’s not just about the type; the width of the edge, such as the 18mm edge banding, can also play a significant role in user safety.

Delving into Different Edge Types

When discussing width, it’s pivotal to understand the various edge types:

- Beveled Edge: This edge tapers from the top surface of an object to its side, creating a symmetrical slope. It’s commonly found in mirrors and furniture.

- Rounded Edge: Edges that are smooth and rounded, prioritizing safety and aesthetics.

- Chamfered Edge: With a distinct angular cut, chamfered edges are often used in carpentry and architecture for both functionality and design.

- Bullnose Edge: A fully rounded edge, bullnose designs offer a continuous curve that’s both appealing and safe.

- Raw or Live Edge: Maintaining the natural form of the material, especially wood, this edge type celebrates imperfections and offers rustic charm.

Width is more than just a measurement; it’s a critical design element that influences the end user’s experience. When it comes to immaculate results, there’s no room for compromise. This is the motto at Easy Spray. With over a decade of experience under our belt, we’ve mastered the art of flawless edging. The next time you think of MDF cut to size or edge banding, remember — width always matters, and so does expertise. Choose wisely.

FAQ

What is edge banding?

Edge banding is a process of applying a band, often made of wood veneer, plastic, or other materials, to the edges of furniture, usually made of MDF or plywood, to give it a finished look.

How does the width of edge banding affect the furniture?

The width plays a significant role in the furniture’s functionality, aesthetics, and performance. It’s not just about size but purpose, design, and function.

Can edge banding be applied to any material?

While edge banding is commonly applied to MDF and plywood, it can be used on various materials. The choice often depends on the furniture’s design and intended use.